Swingarm

- knackeredMk1

- Super Moderator

- Reactions:

- Posts: 4185

- Joined: 03 Nov 2006, 17:41

- Bike Owned: Modified Mk1

Swingarm

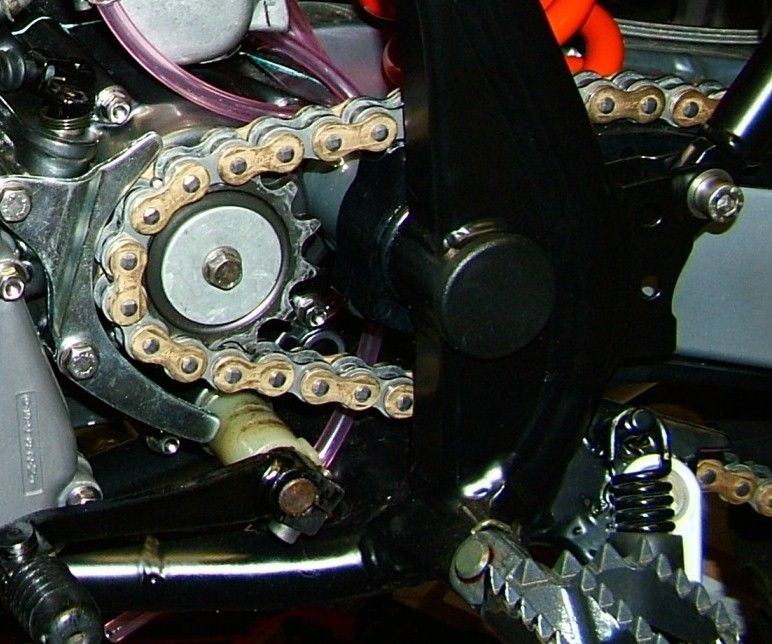

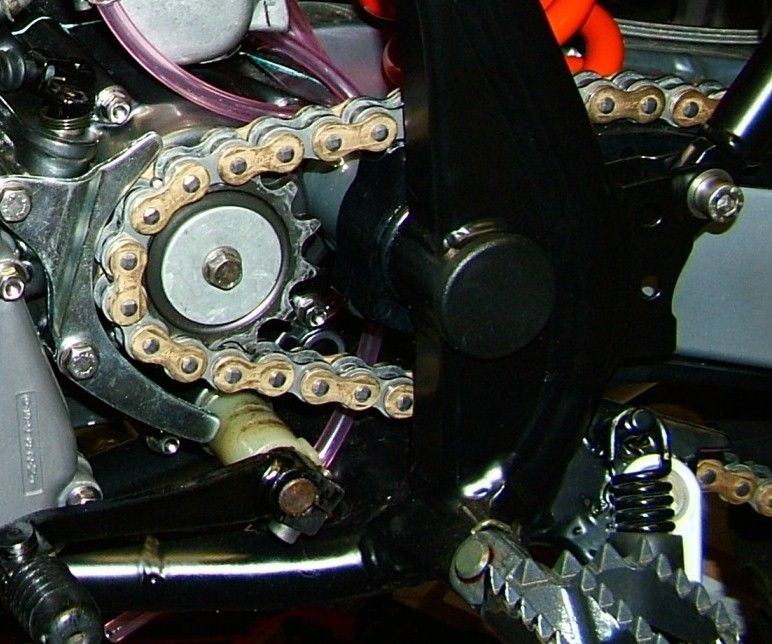

The swingarm and linkage of the Mk1 is unique but those of the other Mks are completely interchangable as they are the same. The mounting points on the frame are the same for all Mks so with a bit of cutting and welding to relocate the top shock mount on a Mk1 you can use the entire rear suspension of a Mk2.

Swingarms on CRMs are prone to seizing. Especially the bushes stick to the swingarm bolt. This is not helped by the bikes coming from factory without any lubrication .

.

This is one area to check when bying a CRM as they can be really difficult to fix. Experiences are listed below:

From Dietcoke - I got a whole bunch of copper 1p pieces ( about 25 ). Stack them up and tape them together to create a makeshift drift. As it's copper its softer than the steel pin, so shouldn't cause the damage. Soak bolt with Wd40 overnight. In the morning give it a few heavy twats using the drift and hammer. Mine popped out no problem, some are less fortunate. Good luck

Superbob - Well if u don't want to damage the threads put the nut on the first few threads and the hit it with ur hammer that should be ok to get u started a little way.

Twistednuts - Every night this week ive sprayed wd40 down each end of the seals, used a full can so far! The nut was easy to come off, so i thought id cracked it, but no, spindle wouldnt budge. Got impact socket on via compressor an got spindle to turn.. whey hey!! cracked it.. or so i thought! The bugger is just spinnin on the bushes. Can now just about turn it with a normal socket wrench, an it seems to be spreading frame apart, guess its cos theres no mountings at the back. I`ve put nut back on spindle a few threads an hit f!*k out of the nut, its pretty knackered now, so tomorrow im gonna try the bike on its side with scaffoldin tube on frame.

FallenMiketheBike - Drill a hole through the bearing casing to try to get some penetrating oil through the bearings to the bushes that have seized. Use of heat is often useful.

KnackeredMk1 - I had a completely rusted up swingarm bolt an a bike. 15 minutes with an angle grinder with a 1mm disk for cutting stainless steel and it was off. 4 cuts into the swing arm, 1-2mm away from and parallel to the frame and the engine mounts, is all it took. Make sure you cut with the swingarm at its extreme of travel each way. Swingarms are plentiful and relatively cheap. It is just not worth the potential damage to the frame and all the sweat and aggro to do it any other way unless a few hits with a hammer and drift gets it out after soaking it in penetrating oil with some localised heat.

Nicko - The nut end of my bolt has a hole drilled into it. the drift used was a length of steel reinforcing bar one end of which was ground to a point. this fitted in the hole, avoided messing up the threads, and provided a very positive connection to the bolt. (You can end up jamming the drift bar in the end of the spindle. You can also spread the threaded end of the bolt if you are trully brutal ).

).

Swingarms on CRMs are prone to seizing. Especially the bushes stick to the swingarm bolt. This is not helped by the bikes coming from factory without any lubrication

This is one area to check when bying a CRM as they can be really difficult to fix. Experiences are listed below:

From Dietcoke - I got a whole bunch of copper 1p pieces ( about 25 ). Stack them up and tape them together to create a makeshift drift. As it's copper its softer than the steel pin, so shouldn't cause the damage. Soak bolt with Wd40 overnight. In the morning give it a few heavy twats using the drift and hammer. Mine popped out no problem, some are less fortunate. Good luck

Superbob - Well if u don't want to damage the threads put the nut on the first few threads and the hit it with ur hammer that should be ok to get u started a little way.

Twistednuts - Every night this week ive sprayed wd40 down each end of the seals, used a full can so far! The nut was easy to come off, so i thought id cracked it, but no, spindle wouldnt budge. Got impact socket on via compressor an got spindle to turn.. whey hey!! cracked it.. or so i thought! The bugger is just spinnin on the bushes. Can now just about turn it with a normal socket wrench, an it seems to be spreading frame apart, guess its cos theres no mountings at the back. I`ve put nut back on spindle a few threads an hit f!*k out of the nut, its pretty knackered now, so tomorrow im gonna try the bike on its side with scaffoldin tube on frame.

FallenMiketheBike - Drill a hole through the bearing casing to try to get some penetrating oil through the bearings to the bushes that have seized. Use of heat is often useful.

KnackeredMk1 - I had a completely rusted up swingarm bolt an a bike. 15 minutes with an angle grinder with a 1mm disk for cutting stainless steel and it was off. 4 cuts into the swing arm, 1-2mm away from and parallel to the frame and the engine mounts, is all it took. Make sure you cut with the swingarm at its extreme of travel each way. Swingarms are plentiful and relatively cheap. It is just not worth the potential damage to the frame and all the sweat and aggro to do it any other way unless a few hits with a hammer and drift gets it out after soaking it in penetrating oil with some localised heat.

Nicko - The nut end of my bolt has a hole drilled into it. the drift used was a length of steel reinforcing bar one end of which was ground to a point. this fitted in the hole, avoided messing up the threads, and provided a very positive connection to the bolt. (You can end up jamming the drift bar in the end of the spindle. You can also spread the threaded end of the bolt if you are trully brutal

- knackeredMk1

- Super Moderator

- Reactions:

- Posts: 4185

- Joined: 03 Nov 2006, 17:41

- Bike Owned: Modified Mk1

Re: Swingarm

The trick is to keep the swing arm bolt greased and lubricate the bearings frequently. So service once a year.

Standard bearings are 12mm wide (20x26x12) but you can get 18mm wide (20x26x18) bearings with a seal on one side. This gives a little more support but also better sealing if you put the seal side to the 'outside' of the swingarm.

In Japan when racing CRMs owners sometimes put 4 bearings on each side, as opposed to 2. This apparently makes the swingarm less flexible when travelling over rough ground. I've found some 20x26x20 bearings which I'll be using in the next swingarm bearing change (2 for each side with seals on each end (HK20202RS)) .............

My bike has a hollow swing arm bolt (later models tend not to have these). It is welded closed at one end and has a grease nipple threaded into the other end. It has some holes drilled through it, opposite the bearing positions so that you can pump grease into the bearings/bushes. If you do this too energetically you can push the seals out.

You can limit dirt/water from entering bearings etc by putting caps on the frame where the swingarm is recessed. These are available from furniture manufacturers, electronic component and welding accessory retailers.

Standard bearings are 12mm wide (20x26x12) but you can get 18mm wide (20x26x18) bearings with a seal on one side. This gives a little more support but also better sealing if you put the seal side to the 'outside' of the swingarm.

In Japan when racing CRMs owners sometimes put 4 bearings on each side, as opposed to 2. This apparently makes the swingarm less flexible when travelling over rough ground. I've found some 20x26x20 bearings which I'll be using in the next swingarm bearing change (2 for each side with seals on each end (HK20202RS)) .............

My bike has a hollow swing arm bolt (later models tend not to have these). It is welded closed at one end and has a grease nipple threaded into the other end. It has some holes drilled through it, opposite the bearing positions so that you can pump grease into the bearings/bushes. If you do this too energetically you can push the seals out.

You can limit dirt/water from entering bearings etc by putting caps on the frame where the swingarm is recessed. These are available from furniture manufacturers, electronic component and welding accessory retailers.

-

fallenmikethebike

- NWAA Supporter

- Reactions:

- Posts: 3520

- Joined: 02 Dec 2007, 16:02

- Bike Owned: MK3

- Location: Mid Surrey

Re: Swingarm

Knock the pin 3/4 out, pump grease into the shaft orifice

If you happen to have a spare shaft

IMO.

Mike

VFORCE REEDS-MUGEN HEAD AND BARREL-WHITE POWER-ALL ON MY WISH LIST!!